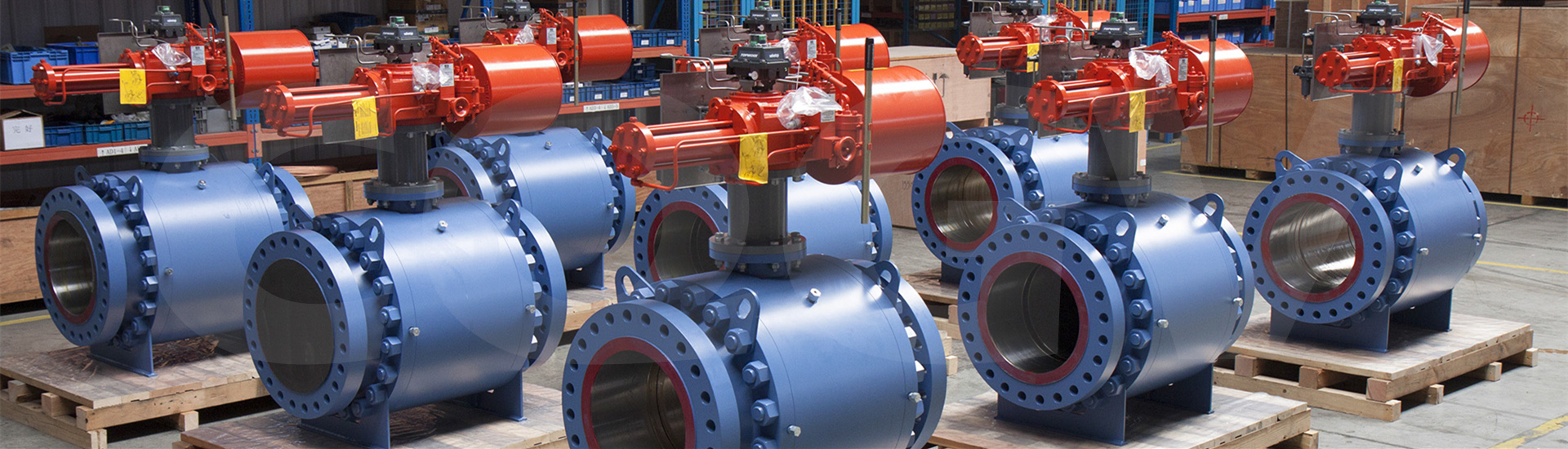

Ball valve features

The opening and closing member of the ball valve is driven by the valve stem and rotates around the axis of the ball valve. It can also be used for fluid regulation and control. The hard-sealed V-ball valve has a strong shear force between the V-shaped core and the metal seat of the hardfacing alloy. It is especially suitable for fiber-containing, micro-solid particles. Etc. The multi-way ball valve not only can flexibly control the switching of the merge, split, and flow directions of the medium, but also can close any channel and connect the other two channels. This type of valve should generally be installed horizontally in the pipeline. Ball valves are classified according to the driving method: pneumatic ball valve, electric ball valve, manual ball valve.

Ball valve features:

1、Wear resistance; since the valve core of the hard seal ball valve is alloy steel spray welding,

The seal ring is alloy steel surfacing, so the hard seal ball valve does not cause too much wear when switching. (It has a hardness coefficient of 65-70)

2、The sealing performance is good; since the sealing of the hard sealing ball valve is manual grinding, it can be used until the valve core and the sealing ring are completely matched. Therefore, his sealing performance is reliable.

3、The switch is light; since the bottom of the seal ring of the hard seal ball valve uses a spring to hold the seal ring tightly with the valve core, the switch is very light when the external force exceeds the preload of the spring.

4、Long service life: It has been widely used in petroleum, chemical, power generation, papermaking, atomic energy, aviation, rocket and other departments, as well as people's daily life.

The pneumatic ball valve is simple and compact in structure, reliable in sealing and convenient in maintenance. The sealing surface and the spherical surface are often closed, which is not easily eroded by the medium, easy to operate and maintain. It is suitable for general working medium such as water, solvent, acid and natural gas, mainly used for cutting off. Or turn on the medium in the pipeline, or use it for fluid regulation and control.

Compared with other types of valves, pneumatic ball valves have angular stroke output torque, which is quick, stable and reliable, and is suitable for a wide range of applications, as well as the following advantages:

1、 The thrust bearing reduces the friction torque of the valve stem, which makes the valve stem smooth and flexible for long-term operation.

2、 Anti-static function: a spring is arranged between the ball, the valve stem and the valve body, and the static electricity generated during the switching process can be derived.

3、Since the material such as polytetrafluoroethylene has good self-lubricating property and the friction loss with the sphere is small, the service life of the pneumatic ball valve is long.

4、the fluid resistance is small: pneumatic ball valve is the smallest of the fluid resistance of all valve classification, even the reduced diameter pneumatic ball valve, its fluid resistance is quite small.

5、Stem seal is reliable: Since the valve stem only rotates and does not move up and down, the packing seal of the valve stem is not easy to break, and the sealing capacity increases with the increase of the medium pressure.

6、The sealing performance of the valve seat is good: the sealing ring made of elastic material such as PTFE is easy to seal, and the valve sealing ability of the pneumatic ball valve increases with the increase of the medium pressure.

7、The fluid resistance is small, and the ball valve with full diameter has basically no flow resistance.

8、Simple structure, small size and light weight.

9、close and reliable. It has two sealing faces, and the sealing surface material of the ball valve is widely used in various plastics, and has good sealing performance and can achieve complete sealing. It has also been widely used in vacuum systems.

10、easy to operate, rapid opening and closing, high-performance ball valve from full open to full off as long as 90 ° rotation, easy to control over long distances.

11、the maintenance is convenient, the ball valve is simple in structure, the sealing ring is generally active, and it is convenient to disassemble and replace.

12、When fully open or fully closed, the sealing surface of the ball and the valve seat is isolated from the medium. When the medium passes, it will not cause erosion of the sealing surface of the valve.

13、a wide range of applications, from small to a few millimeters, up to a few meters, from high vacuum to high pressure can be applied.

14、Since the ball valve has wiping property during the opening and closing process, it can be used in a medium with suspended solid particles.

15、The processing precision is high, the cost is expensive, and it is not suitable for use in high temperature. If there are impurities in the pipeline, it is easily blocked by impurities, and the valve cannot be opened.

LATEST NEWS

News

- High pressure ball valve product features2019-04-07

- Check valve working principle2019-03-03

- Stainless steel ball valve seal form2019-03-03

- Butterfly valve structure2019-03-03

- Application of hydrophobic ball valve in power pla2019-03-03

- Pneumatically regulated ball valve works2019-03-03

COUNSELING

Counseling

Tel:+86 577 67952209

E-mail:qgvacc@163.com

Add:Anfeng Industrial Zone, Oubei Town, Yongjia County, Zhejiang Province P.R.China